Using our high-resolution models in CFD or FEA analysis can also mean substantial time and money savings in vehicle design and development. Using our high-quality automotive 3d scanning techniques to build digital assemblies has the potential to solve complex fitment and assembly issues. Various BIW manufacturing issues have been resolved using 3D scanning and inspection methods. Wear and deformation measurements are also achieved using these techniques.

- Easily transition from physical to digital models

- Advanced first article inspection

- Aftermarket product design and development saves time and money

- Wear and deformation measurement with digital 3d measurement

- Digital styling and product design

- Advanced analysis and benchmarking

- Quality control for production parts

- BIW fitment problems

- Complex assembly troubleshooting

Our 3D Scanning Work In the Automotive Sector Includes:

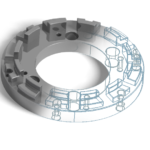

- Engine Blocks

- Pistons

- Turbines

- Interior/exterior body panels

- Seats / Cushions

- Door panels

- Window/Windshield glass

- Console/IP

- Sheet metal / mufflers / bumpers / hoods

- Clay model reverse engineering

- Headlight reverse engineering and inspection

- Mechanisms and assemblies

- Aftermarket product development

Our 3d scanning services help you overcome these difficulties. May it be a BIW problem, component misfit problem, or a host of different size and shape-related problems, we will strive to find a suitable and cost-effective solution for you.

Examples On Why 3D Scanning Can Streamline The Workflow

Full-size clay design models of automobiles can be scanned and reverse engineered into class A digital CAD models, which can further be used to develop the whole vehicle, and the tooling required to produce it. During this process, we can also modify the design to reflect the target market and the ergonomics of the target users. This whole process saves a lot of design iterations and thus person-hours.

First article parts, or in some cases, prototypes, are important in a product development process. The measurement and troubleshooting of these parts ensure that the manufacturing process is working and that the parts conform to the design intent. Since most automotive parts are freeform shaped without primitive geometry definition, they prove to be challenging when measuring them with conventional metrology, like CMM, etc. With our advanced 3d scanning, onsite measurements are done on complex shaped parts, ensuring they meet specifications at this very initial stage.

During the production process, comparisons of as-built parts to CAD models are shown in our fully customizable, easy-to-understand inspection reports, which include: Color plots, Cross-sections, Annotated call-outs, scan-to-cad overlays, dimensioning, advanced GD&T call-outs, 3d pdf models, and more.

If you have any more questions about our automotive 3D scanning process, please contact us.